Alpha Energy

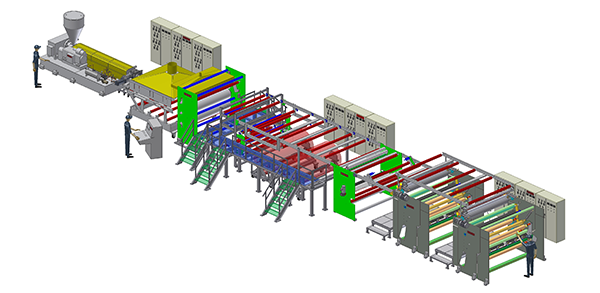

Extrusion lines for production of EVA plastic sheet used in SOLAR PANEL

EVA encapsulation films are intended to have a very simple function, they are to protect the solar panel electrode. This is accomplished by encapsulating the very fragile electrode top and bottom (surrounding) with a film that is fused to the electrode with heat and pressure.

The traditional solar panel is a sandwich made of glass/EVA/electrode/EVA/back panel.

The film must intimately flow into every contour (no voids), be as clear as possible (no yellowing), be sufficiently flexible to handle daily thermal expansion/contraction, be pliable to act as a shock absorber between the glass front panel and the supporting back panel, and do this for a minimum of 25 years.

In order to achieve this, EVA Encapsulation films must have a number of crucial properties when produced. These properties ultimately affect the performance and longevity of the solar panel.

Ensuring these attributes exist from the start can only be achieved when the film is produced on equipment designed and manufactured with these properties incorporated in the design, followed by the use of high quality components, and finally through to the integration of state of the art controls. Anything less will result in a film that does not stand the test of time in the solar panel.

Alpha Marathon's Alpha Energy has been engineered to make certain that EVA Encapsulation Films produced meet today's and tomorrow's requirements.

Alpha Energy design parameters ensures:

- Low gel count

- Processed with a high degree of thermal uniformity to prevent premature cross-linking

- Exceptionally consistent gauge profile

- Minimal shrink characteristics

- Contaminant free film surfaces

- Negligible roll winding deformation

Let Alpha Marathon partner with you by providing its Alpha Energy solution in the production of Encapsulation films.

BENEFITS:

- ALine widths up to 2.3 meters

- Highly stable melt heat uniformity

- Auto profile die for flat film

- Optional twin screw for reactive polymeric materials

- Optional unwind unit for relase liner

- Coextrusion for different surfaces and trim recycling

For more information about how your company can benefit from ALPHA ENERGY or blown and cast extrusion equipment please contact us at (905)738-3682 or marketing@alphamarathon.com

OPEN FOR BUSINESS TO PROVIDE CUSTOMER SERVICE